Foundry Ceramic Sand AFS65

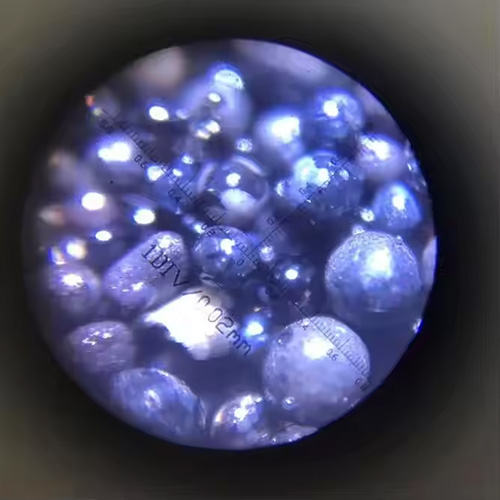

Foundry ceramic sand is a superior casting sand for steel and non-ferrous alloy castings. This type of casting sand is made from fusing and blowing process of bauxite ore at high temperature of 2000 degree. As a refractory material based on alumina, ceramic sand obtains excellent refractory performance. In the meantime, the spherical casting sand make it get advantage of low angularity, higher surface area, and easy to fill into the molding. Ceramic sand gets lower thermal expansion so that it can resist melting iron, steel and other alloys.

Foundry ceramic sand is specialized in core making in molding process, no bake sand casting, resin coated sand casting, etc.

Product Feature of Ceramic sand for No-bake sand casting:

1. High thermal resistance and chemical insert.

2. Low thermal expansion rate.

3. Good flowability and low angularity coefficient.

4. High mechanical strength.

- Dry sand with Low humidity.

- Spherical shape makes it easy to clean with good air permeability.

- Recyclable.

- Reduce resin amount than angular shape sand.

Product Index

Typical chemical composition of Foundry ceramic sand for core making:

|

Item |

Standard Value |

Typical Value |

|

Al2O3 |

70-72 |

70.65 |

|

SiO2 |

10-25 |

21.87 |

|

Fe2O3 |

≤3 |

2.40 |

|

TiO2 |

≤3.5 |

3.32 |

|

K2O |

≤1.5 |

1.20 |

|

CaO |

≤0.45 |

0.28 |

|

MgO |

≤0.35 |

0.32 |

|

Na2O |

≤0.10 |

0.08 |

Typical physical properties of Foundry ceramic sand for core making

|

Refractoriness |

≥1800 °C |

|

Mohs hardness |

6.5-7.5 |

|

Specific gravity: |

3.4g/cm3 |

|

Bulk density(LPD): |

1.95-2.05 g/cm3 |

|

Color: |

black brown |

|

Grit shape: |

spherical Ball |

|

PH value |

7.3 |

|

Thermal expansion coefficient |

6×10-6 /°C(20-1000°C) |

|

Thermal conductivity |

0.698W/M.K(1200°C) |

|

Thermal expansion ratio |

0.13%(10 min at 1000°C) |

|

coefficient of angularity |

≤1.1 |

|

Roundness |

Min 95% |

Product Applications

Applications of Ceramic sand for No-bake sand casting:

- Work with resins such as the furnace, Alkaline-phenolic, water glass for core making.

- High alloy cast steel and carbon steel.

- Low carbon steel and stainless steel valve parts.

- Stainless steel, manganese steel, high chromium cast iron.